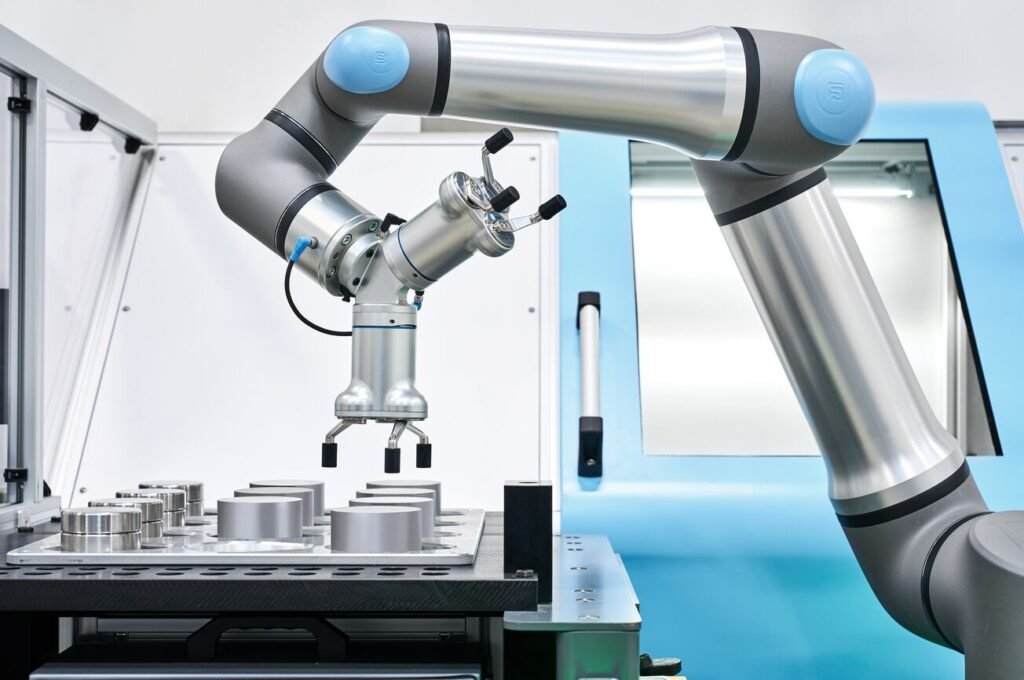

Machine tending acts as the vital production pipeline in many manufacturing companies, ensuring a seamless flow of materials to various types of industrial equipment, including computer numerical control (CNC) and injection molding machines. However, loading materials incorrectly can lead to machinery jams and misalignments, resulting in faulty products, increased scrap rates, equipment damage and downtime, unexpected costs, and even safety hazards.

Part Variability: Irregular shapes or sizes may require advanced vision and adaptive gripping.

Cycle Time Synchronization: Robot and machine cycles must be closely matched for efficiency.

Changeover Time: Adjusting to different parts or machines can require reprogramming or hardware changes.

Initial Cost and ROI: Upfront investment in robots and integration may be high but is usually offset by long-term savings.